Universal Testing Machine–

Brinell Hardness Tester–

Simulation software Brinell Hardness Tester - Max range: max 3000 kgf in steps of 250 kgf. Optical, max test piece height: 380 mm, L.C.=0.01, Machine wt.=450 kg. Ball of indentation = Hardened steel ball: 5 mm & 10 mm. Allows modelling of thermal heat transfer including radiation with few factors, liquid flow.

Max impact energy of pendulum-300 joules, minimum value of scale gradetion-0.5 joules, angle of drop of pendulum- 140°, Machine wt.=450 kg

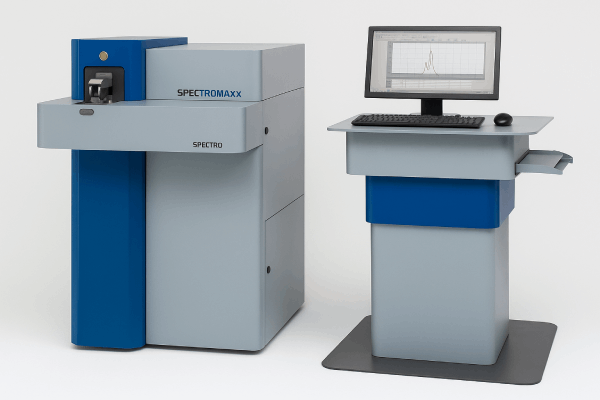

Spectrometer- Spectromax Germany

Corrosion test according to ASTM A262 Practice A, B, C, E, F. Pitting Corrosion Test as per ASTM G48 Method

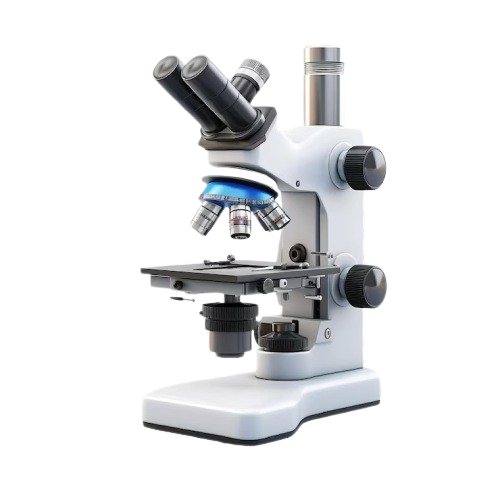

Examination of material structure